Vacuum resin impregnation of marble, granite and stone

Technology presented today is a procedure for impregnating marble by means of an air vacuum: thanks to the vacuum, the resin penetrates deeper into the stone’s fine cracks, thus ensuring better restoration of the slabs and better polishing.

The resin-saturated cracks also prevent the infiltration of moisture from the laying surface.

Our customer has patented and developed the systems for vacuum resin coating, with the resin material being spread on the surface of the granite slabs (not by immersion), and has developed the characteristics of the resins to be used and the parameters of the process in its own research centre.

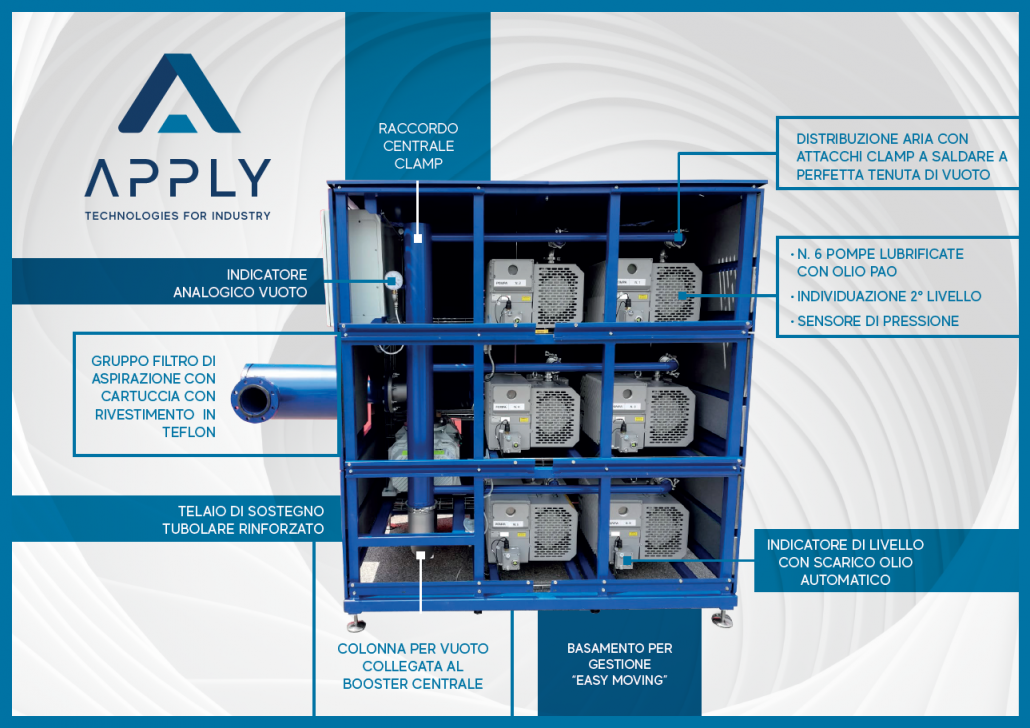

Apply, for this process and this plant, supplies the vacuum unit that you can see in the following photos:

Air distribution with vacuum-tight soldered clamp connections – Six pumps lubricated with pao oil – Oil level indicator – Pressure sensor – Oil level indicator with automatic oil drain – Base for “easy moving” handling – Vacuum column connected to central booster – Reinforced tubular support frame – Suction filter unit with Teflon-coated cartridge – Analogue vacuum indicator – Central clamp connection

PLC control panel for vacuum management, operation optimisation, master/slave pump management – Inspection porthole – Removable panels with sound absorber

Vacuum-tight connection clamp fittings – Internal wiring via concealed channel

Stainless Steel Flange Fittings – Booster unit with inverter for optimised modulation of vacuum performance and electrical absorption